Introduction

Have you ever wondered how a professional ping pong table is made? Whether you’re a passionate player or just curious about the manufacturing process, understanding how these tables are crafted can enhance your appreciation for the game. This blog will guide you through the six-step process of making ping pong tables, detailing each stage from material selection to the final touches, ensuring you gain insights into this fascinating craft.

The Six Steps to Crafting Ping Pong Tables & Table Tennis Tables – Best Manufacturing

1. Material Selection

The first step in making a ping pong table & table tennis tables involves selecting high-quality materials. The primary components include:

- Tabletop: Typically made from MDF (Medium Density Fiberboard) or plywood, which provides a smooth playing surface.

- Frame: Constructed from sturdy materials like steel or aluminum to ensure durability and stability.

- Legs: Often made from metal or solid wood, designed to support the weight of the table.

Choosing the right materials is crucial for achieving optimal performance and longevity.

2. Cutting and Shaping

Once materials are selected, the next step is cutting and shaping them to the desired dimensions. This involves:

- Precision Cutting: Using saws and CNC machines to cut the tabletop and frame to exact specifications.

- Shaping Edges: Ensuring that all edges are smooth and rounded to prevent splinters and enhance safety.

This stage is vital for ensuring that the table meets international standards for competitive play.

3. Surface Finishing

The surface finishing process enhances both aesthetics and functionality. Key aspects include:

- Sanding: The tabletop is sanded down to create a perfectly smooth surface, essential for consistent ball bounce.

- Coating: A specialized paint or laminate is applied to protect against wear and tear while providing a professional look.

This step not only improves the table’s appearance but also contributes to its performance during play.

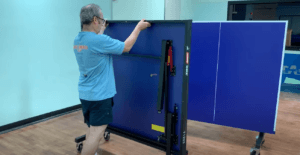

4. Assembly

After finishing, it’s time for assembly. This involves:

- Joining Components: Attaching the legs to the frame and securing the tabletop in place.

- Quality Checks: Inspecting all connections to ensure stability and safety.

Proper assembly is critical as it affects both the durability of the table and its usability during games.

5. Testing and Quality Control

Before a ping pong table can be shipped out, rigorous testing is conducted:

- Bounce Tests: Ensuring that the ball bounces correctly across different areas of the table.

- Stability Tests: Checking that the table remains stable under various conditions.

This quality control phase ensures that only top-notch tables reach consumers, meeting their expectations for performance.

6. Packaging and Shipping

The final step is packaging and shipping:

- Protective Packaging: Tables are carefully wrapped to prevent damage during transit.

- Shipping Logistics: Coordinating delivery to ensure timely arrival at stores or customers’ homes.

Effective packaging is essential for maintaining product integrity throughout its journey from factory to end-user.

Best Practices for Choosing a Ping Pong Table

When selecting a ping pong table, consider these best practices:

- Look for tables that meet ITTF (International Table Tennis Federation) standards if you’re serious about competitive play.

- Choose a table with adjustable legs for uneven surfaces.

- Consider purchasing from reputable suppliers known for quality craftsmanship.

Key Takeaway: Investing in a high-quality ping pong table can significantly enhance your playing experience.

Common Misconceptions About Ping Pong Tables

Many people have misconceptions about ping pong tables. Here are some clarifications:

- Misconception: All tables are created equal.

- Reality: Different tables serve different purposes; competition tables are built differently than recreational ones.

- Misconception: Price always reflects quality.

- Reality: While higher-priced tables often offer better materials, it’s essential to research brands and specifications.

FAQs

Q: How long does it take to make a ping pong table?

A: The manufacturing process typically takes several weeks, depending on production volume and customization options.

Q: Can I customize my ping pong table?

A: Yes, Yesporting can offer customization options regarding color, size, and branding.

Conclusion

Understanding the intricate process of making ping pong tables not only enriches your knowledge but also helps you make informed decisions when you purchasing. From material selection to final testing, each step plays a crucial role in delivering a high-quality product that enhances your game.

If you’re looking for top-notch custom ping pong tables or other table tennis equipments tailored to your needs, visit tennistablesupplier.com. With our expertise in custom manufacturing and export experience, we ensure you receive a product that meets your expectations perfectly. Don’t hesitate—contact us today!